The use of LEDs in sensing and inspection applications has grown significantly, particularly where an application must rely on short-wavelength infrared (SWIR) wavelengths. In this article, we outline some of the most popular applications and find out what role Ushio’s Epitex SWIR LEDs play in them.

SWIR LEDs for Liquid Level Inspection

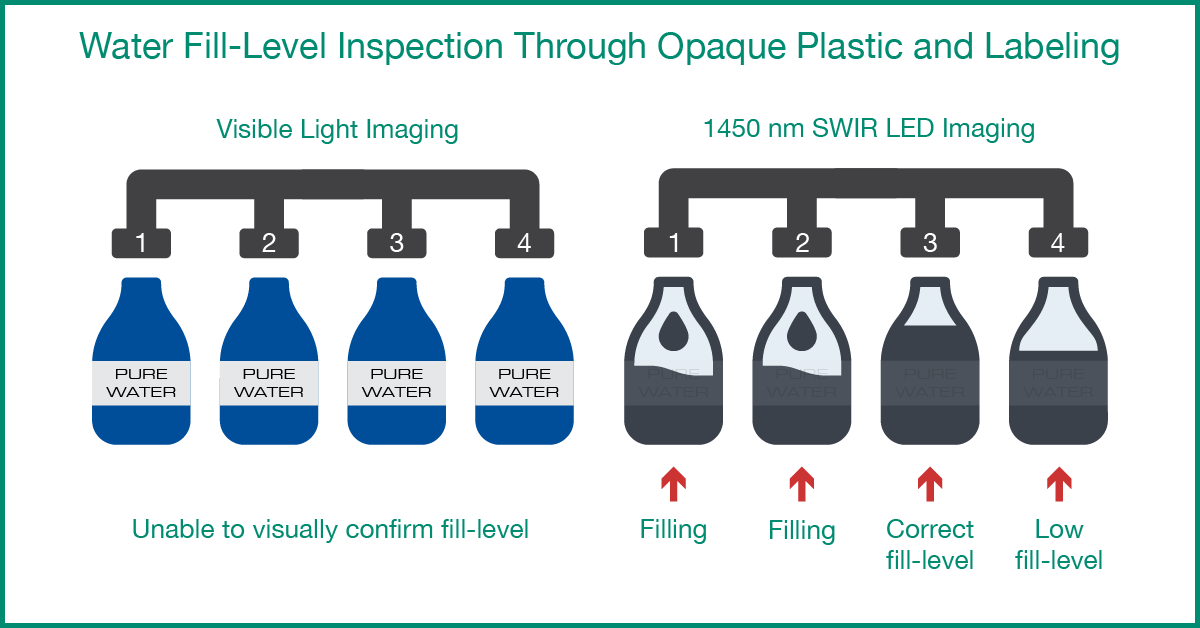

Accurate measurement of liquid within a container is not a particularly easy task. When the container is transparent and the process is slow, human visual confirmation may be possible; however, on modern production lines, containers are opaque and moving at high-speed.

To streamline this application, Ushio has mastered the art of placing up to three different chips into one package. The chips are an assortment of SWIR LEDs and sensors, so each package effectively reduces its occupied space on a circuit board by two-thirds.

Independently pulsed light-emitting chips illuminate the subject, while a sensor, or high-speed camera, captures a spectroscopic image. With this technology, it is possible to analyze various material components in greater detail by cycling through different SWIR wavelengths.

For a closer look at how Ushio Epitex SWIR LEDs perform in liquid level inspection applications, and which wavelengths to look out for, please visit https://swir-led.com/liquid-level-inspection/

SWIR LEDs for Silicon Wafer Defect Inspection

There are various types of silicon defect inspection, such as detection of cracks and internal defects in the wafers themselves, or the detection of defects in circuits formed with different materials on silicon substrates.

Typically, defects are detected by acquiring a transmission image of the area to be measured. This could be an image of an entire wafer, or a small area measuring only a few microns. When the area of interest is that small, microscopic optics are an essential part of the detection system, while an InGaAs area sensor can be relied on to detect even the smallest defects.

SWIR LEDs illuminate the target area of the Si wafer and the transmitted image is captured by an InGaAs photodetector. In principle, any SWIR wavelength longer than 1100 nm will transmit through silicon, but longer wavelengths may be used depending on the impurities in the silicon and the different materials that form the circuit.

Take a closer look at Ushio Epitex SWIR LEDs and their role in silicon defect inspection applications at https://swir-led.com/silicon-defect-inspection/

LEDs for Optical Sorting Systems

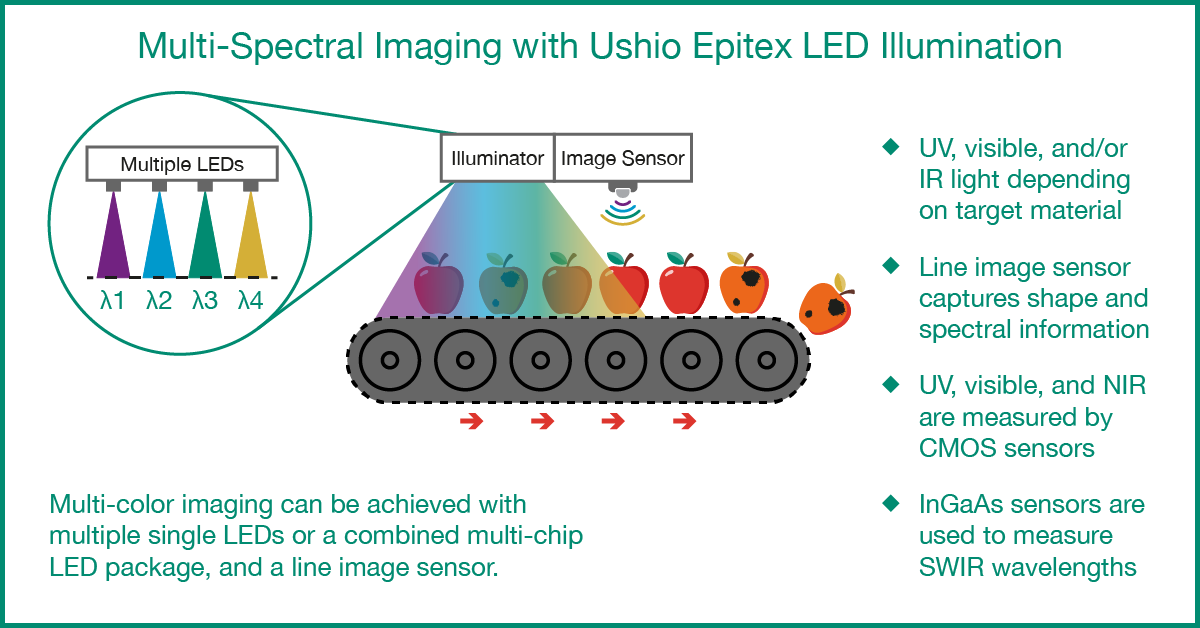

Optical sorting is a system that detects the quality and/or presence of foreign substances based on spectroscopic information. Most importantly, manufacturers of optical sorting systems are interested in the properties of light absorption, transmittance, and reflectivity.

In order to obtain spectroscopic information, illumination using a combination of LEDs with multiple wavelengths, from ultraviolet (UV) to visible and infrared (IR) is used. In particular, SWIR is used for the quality inspection of foodstuffs because this band of wavelengths is mostly absorbed by organic materials.

Typically, a large number of LEDs are arranged in a line perpendicular to a conveyor belt. The LEDs, emitting a range of wavelengths, sequentially illuminate the object. The object is captured as a series of images, each contributing spectroscopic analysis. The image capture is achieved using a line image sensor, specifically an InGaAs line sensor when SWIR measurement is required, which is typically also installed perpendicular to the transport direction.

Based on predetermined quality attributes, the transported objects are assessed and selected for retention or rejection by the mechanical sorter, should they fail to meet the required standards. A detailed article studies the benefits of LED based optical food sorting at https://swir-led.com/optical-food-sorting/, where you will also find a list of the key absorption wavelengths for organic materials.

SWIR LEDs for Road Surface Condition Sensing

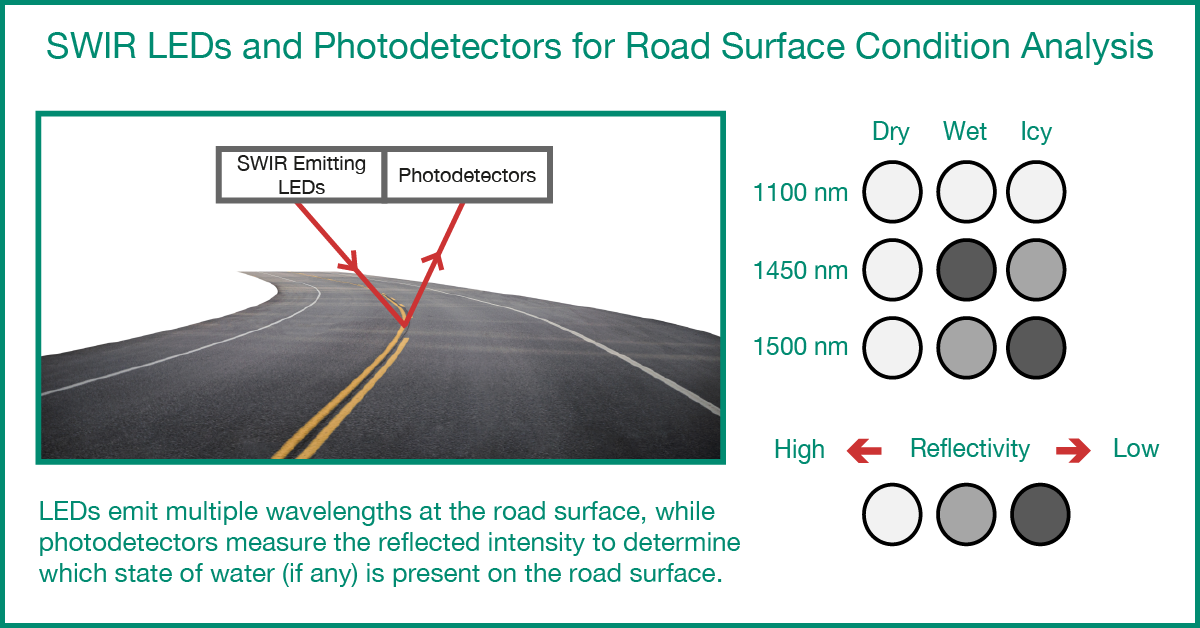

Multiple SWIR wavelengths are emitted at the road by LEDs, with the reflective intensity of each wavelength measured by photodetectors. The photodetectors can be integrated into the same Ushio Epitex package as the LEDs or positioned nearby in their own package. The most important wavelengths in this application fall within the absorption bands of water and ice, which are 1450 nm and 1500 nm, respectively.

Based on the absorption of each wavelength, it is determined whether the target is water or ice. A third wavelength is needed to serve as a reference point for the amount of light reflected from the road itself.

Visit https://swir-led.com/optical-food-sorting/ to learn more about the role of SWIR LEDs in road surface condition sensing.

Contact Ushio about SWIR LEDs for Sensing and Inspection Applications

If you would like to make an inquiry regarding the suitability of Ushio’s SWIR LEDs for your road surface condition sensing applications, please contact us here.