UV LED UniJet series

UV LED modules are used for curing UV reactive inks, lacquers and coatings, as well as UV adhesives and potting compounds. Typical applications include inkjet printing processes and surface coatings or finishes.

Ushio has decades of experience and invests continuously in research and development. With the new UV LED UniJet series, the company offers a further optimised product portfolio. The modules are characterised by a compact and lightweight design, dimmability, peak irradiance, stability and homogeneous radiation distribution as well as a service life of over 10,000 hours. All modules are available with different UV doses and intensities and in various standard sizes.

Available with different UV doses and intensities

Various standard sizes

Service life of over 10,000 hours

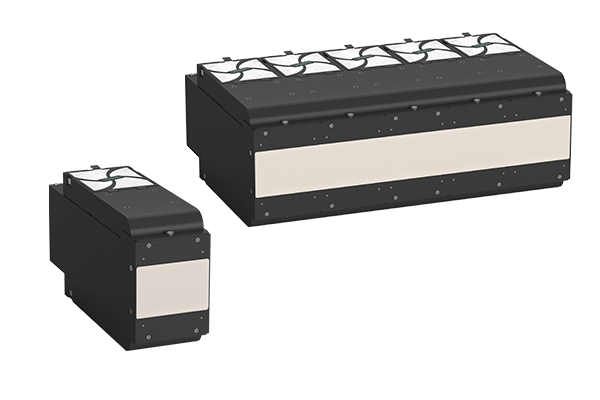

UniJet E series

Specially designed for pinning and 3D printing processes. HD (high dose) versions with high accumulation of UV

irradiance over a wider area, HC (high condensing) versions for high peak irradiance through line-shaped focussing of the UV radiation. Flexible and optimised linking of individual modules with excellent homogeneity of light distribution, even at the point of connection between modules.

Features

- 10-100% dimmable

- Optimised linking through frameless design

- Available in HD and HC version

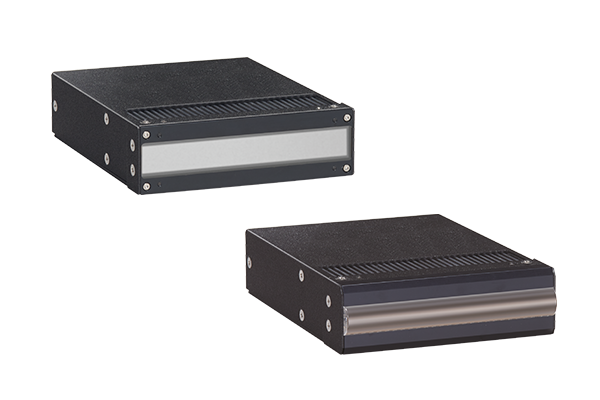

UniJet iC series

Particularly lightweight and air-cooled modules for final curing applications. Due to their compact size and reduced weight, these LED modules are particularly suitable for applications on print carriages.

Features

- Industry´s smallest model for final cure

- Intensity of up to 14.5 W/cm² at a working distance of 5 mm

- 10-100% dimmable

- Compact design, lightweight

- Optimised linking through frameless design

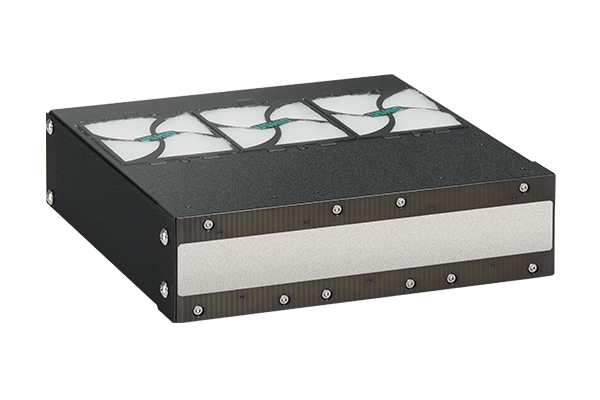

UniJet iIII series

Air-cooled modules with high intensity and dose.

Low intensity loss even at longer working distances.

Features

- Intensity of up to 17.4 W/cm² at a working distance of 5 mm

- Less than 20% intensity loss up to a working distance of 15 mm

- Reduced operating noise due to temperature-controlled cooling

- 14-100% dimmable

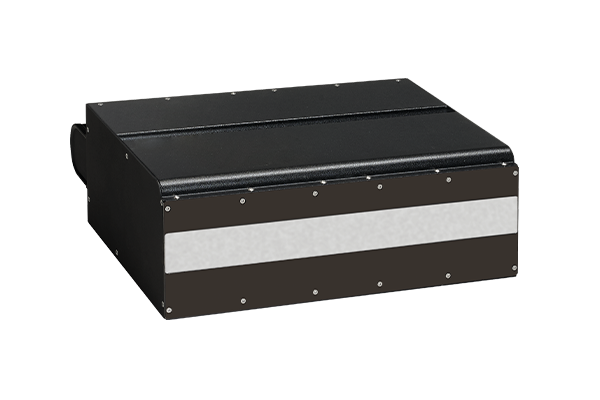

UniJet iIV series

By using highly efficient components, it was possible to achieve energy-saving operation while at the same time reducing the size of the modules. Due to their high intensity and high dose, the modules can be used instead of water-cooled models or conventional UV lamps.

Features

- Intensity of up to 18.5 W/cm² at a working distance of 5 mm

- Highest dose of the industry: Achieves approx. twice the UV dose compared to the less expensive iC series

- Lightweight and compact design: 25% more compact and lighter than iIII modules

- Reduced operating noise due to temperature-controlled cooling

- 12-100% dimmable @ 395 and 385 nm; 17-100% dimmable @ 365 nm