USHIO launches the vanguard in UV-LED print drying solutions with superior illuminance and dosage

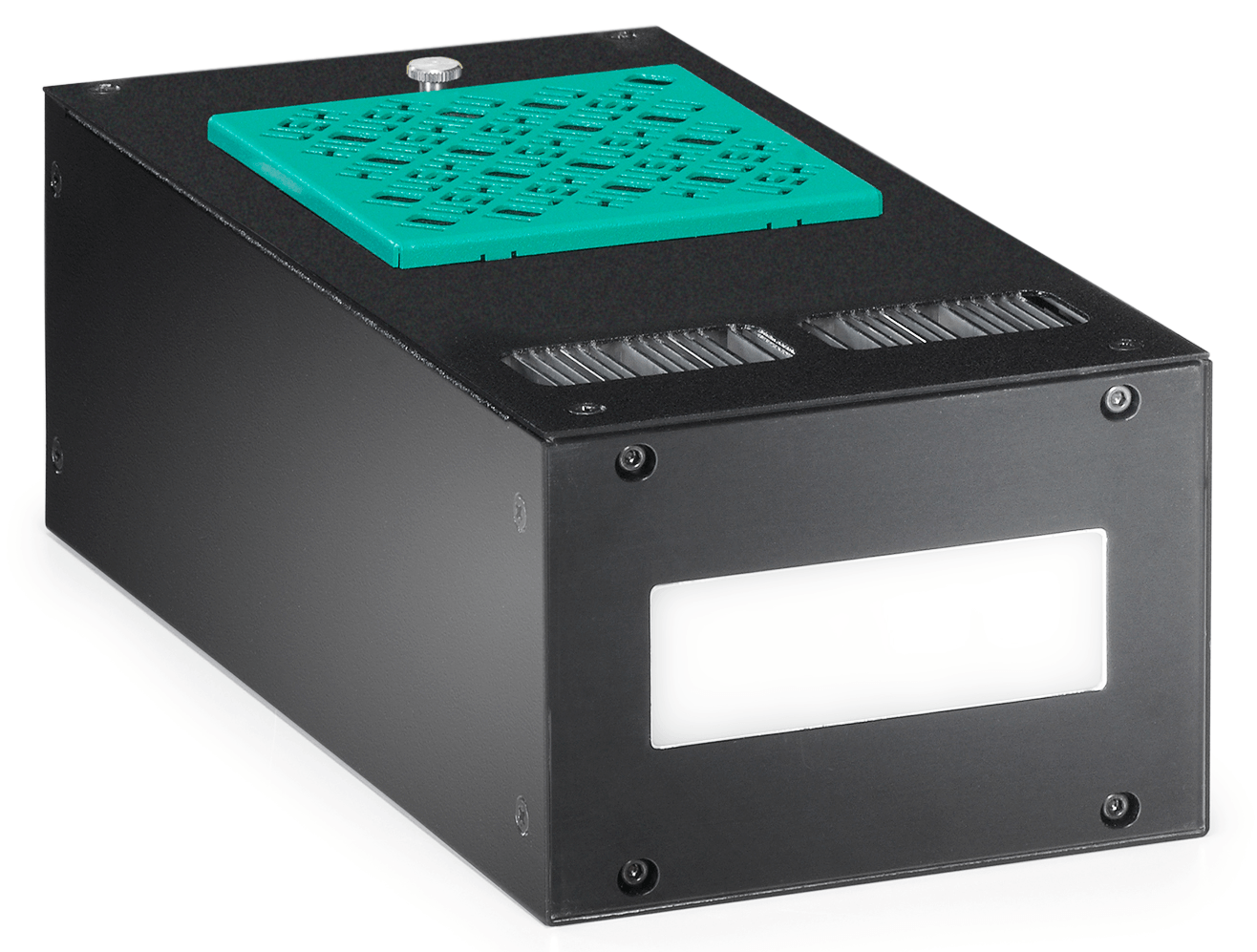

Munich – October 14th , USHIO Europe introduced the “UniJet i-III” at the InPrint show. The new air-cooling UV-LED drying device for printing was launched as part of its new “UniJet Series” of high-performance drying devices that achieve the highest level of illuminance, as well as dosage among other similar devices in the industry. As the printing industry transitions from printing with oil-based inks to UV printing, conventional light sources for ink hardening are being replaced with LEDs, both to satisfy restrictions on VOCs and environmental restrictions pertaining to the reduction of CO2 emissions and elimination of Mercury. Furthermore, replacement is rapidly proceeding in the ink-jet printers used in the digital printing industry. However, the air-cooling UV-LEDs that have been adopted in ink-jet printers are lacking in illuminance and dosage compared to UV lamps, and because of additional attenuation of illuminance that occurs due to issues involving distance from printed media, they have failed to exhibit hardening performance equal to or greater than UV lamps.

Ushio Europe have levergaed their accumulated store of optical design technologies such as lenses and high-density mounting technologies for LEDs, to develop a UV-LED drying device that achives a 40% increase in dosage compared to the company’s previous products. Additionally, the industry top energy delivery of 17 W/cm2 is achieved at practical working distance (5mm), and by reducing attenuation even at 15 mm to less than 20%. As a result, in addition to achieving high illuminance and light integral equivalent to conventional UV lamps, highly uniform irradiation can be applied to the print media, making it possible to achieve high productivity and irridation performance even in situations involving media that are ofset, deflected, or of three-dimensional form.

USHIO Europe will continue leveraging its expertise in light to contribute to the environment and energy conservation in the printing industry.

Main Features

- Achieves illuminance of 17 W/cm2, the industry’s highest level delivering 17 W/cm2 at a practical irradiation distance of 5mm, our unique design realises the industry’s highest level of illuminance.

- Achieves a dosage level greatly exceeding that of previous air-cooling modules. Ultra high-density LED mounting and a unique cooling design maximises performance, resulting in a 40% greater light integral than Ushio’s previous products.

Attainment of a high light integral, the most important element of performance in UV curing, contributes to increased printing productivity and quality. - Ushio’s proprietary optical design technology provides high performance at practical irradiation distances.

Designed to keep illumination attenuation under 20% for irradiated surfaces within the range of 5 to 15 mm that accords with actual conditions, the device achieves highly stable UV radiation.

Ushio’s proprietary optical system assures efficient and highly uniform irradiation of the work surface from each UV-LED. Constant irradiation performance is assured even in cases where the media is offset, deflected, or even of an embossed or other 3D nature.

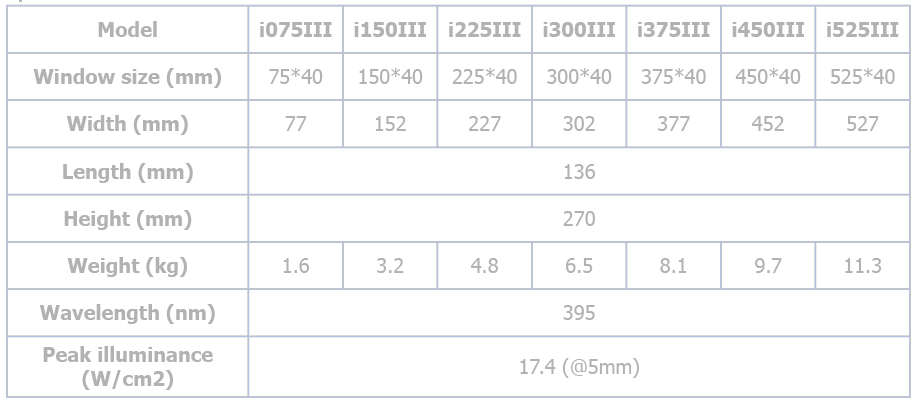

Specifications