Food Treatment

In the food industry, precision and safety are paramount. Advanced lighting technologies play a crucial role in ensuring hygiene, efficiency, and quality control in food treatment, namely commercial food service, inspection & sorting, processing, and packaging stages.

Precision and safety in the food industry

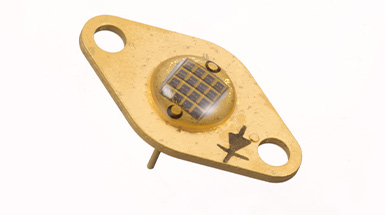

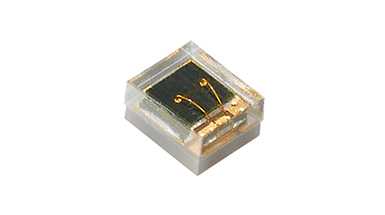

Food sorting is the process of categorizing food products based on specific attributes such as size, shape, colour, weight, or quality. Industrial lighting technologies like laser diodes, cameras, and infrared sensors to detect and remove defective or contaminated items. This ensures consistent product quality, reduces waste, and meets safety and compliance standards.

Efficient processing and quality assurance

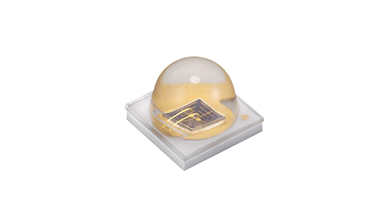

Food processing involves transforming raw ingredients into consumable products through techniques such as cooking, freezing, drying, or packaging. In these processes technologies like infrared heating, UV sterilization, and automated systems enhance efficiency, maintain nutritional value, and ensure food safety by eliminating contaminants and extending shelf life.

Modern packaging technologies for freshness and safety

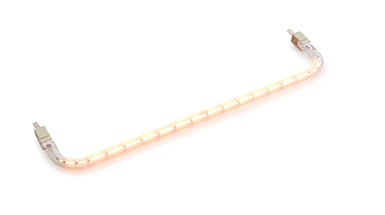

Food packaging protects products during storage and transport while preserving freshness and quality. Modern packaging uses technologies like UV sterilization of foils, plastic packaging, and bottle tops to name a few for hygiene, laser diodes for precise sealing, and LEDs for quality inspection. These advancements ensure durability, reduce waste, and enhance consumer appeal with safe, attractive, and eco-friendly designs.

Keeping warm and hygiene in professional catering

Food presentation in professional catering requires technologies like infrared heating to maintain optimal serving temperatures, and UV sterilization to ensure hygienic preparation.