Curing & Coating

Coating and curing processes are essential in many industries due to their efficiency and versatility. In the automotive sector, they are used for protective coatings on car parts, headlights, and paint finishes. In electronics, these processes are vital for encapsulating components, applying conformal coatings, and bonding circuit boards. The printing industry relies on them for curing inks, varnishes, and overcoats on packaging, labels, and publications. In the medical field, they play a key role in producing medical devices, dental restorations, and protective coatings for instruments. Additionally, they are used in furniture and woodworking for UV-cured finishes, in aerospace for high-performance coatings on aircraft parts, and in packaging for durable, glossy finishes on containers. These applications demonstrate the wide-ranging benefits of coating and curing, including improved quality, durability, and production speed.

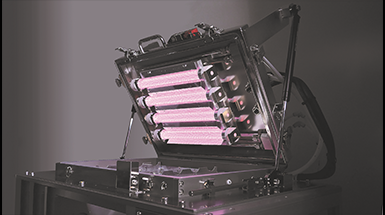

Curing and coating with IR technology

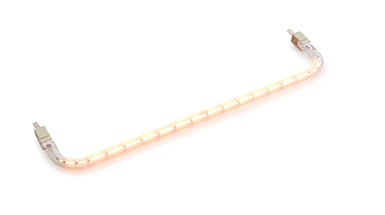

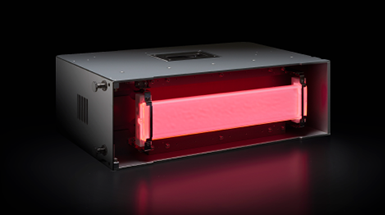

Infrared (IR) lamps is widely used for drying and curing coatings due to its precision, speed, and energy efficiency. They are effective in drying water-based paints, adhesives, and powder coatings by directly heating the materials thereby reducing processing times. IR radiation provides uniform curing even on complex surfaces and allows for targeted heating, minimizing thermal damage.

The benefits of IR lamps include faster processing, reduced energy consumption, versatility with different materials, and eco-friendly operation compared to traditional heating methods.

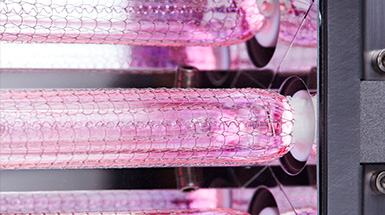

Curing of coatings with UV technology

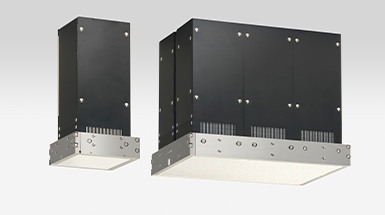

UV curing of coatings is a process that uses ultraviolet light to rapidly harden specially formulated coatings, inks, or adhesives. It begins with applying a UV-curable resin, which contains photosensitive compounds called photoinitiators, onto a surface. When exposed to UV light of specific wavelengths, the photoinitiators trigger a chemical reaction called polymerization. This reaction causes the resin to harden instantly, creating a durable, high-quality finish.

The process is widely used in industries such as printing, electronics, and automotive, offering advantages like faster curing times, improved surface durability, less heat stress for the cured product and reduced environmental impact compared to traditional heat-based drying methods.

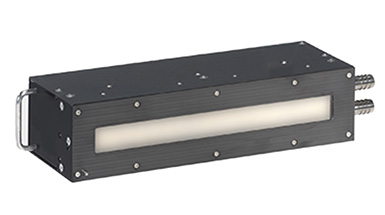

The versatility of Ushio’s products means they can be tailored to meet the specific needs of various industries, from automotive to electronics, and packaging to textiles. By integrating IR and UV technologies into their operations, businesses can achieve faster production times, improved product quality, and significant energy savings. This technological advancement not only boosts efficiency but also contributes to a more sustainable and eco-friendly manufacturing process.

contact us