Inspection & Verification

Inspection and verification methods have always been of crucial importance in areas such as quality control, high precision, efficiency and safety. Highly developed technologies are used to achieve the ambitious goal of zero-defect quality. Relevant application areas are endless, but here are some practical examples where industrial light sources are used to support these processes.

Machine Vision

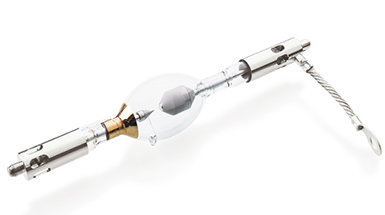

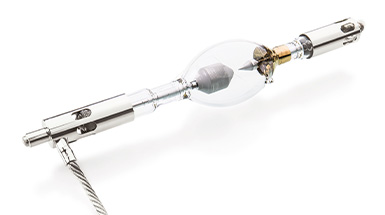

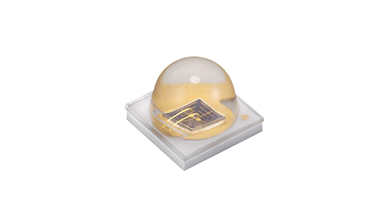

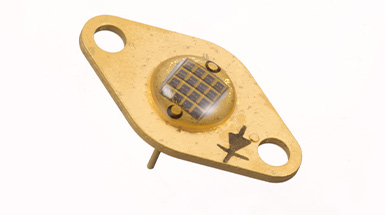

Machine vision systems rely heavily on precise and adaptive lighting to capture and analyze high-resolution images of objects. LEDs provide versatile and adjustable illumination, ensuring proper lighting angles and intensities. LDs are used for edge detection and dimension measurements, while xenon lamps support high-speed imaging in dynamic environments.

Wafer Inspection

Semiconductor wafers require meticulous inspection for defects and surface irregularities. High-intensity LEDs or LDs are used to create structured lighting patterns, such as grids or lines, to detect cracks, scratches, or contamination. Xenon lamps may be used for photolithography processes, ensuring uniform and high-quality exposure.

Passport Verification

Passports undergo detailed inspection using a combination of LED and UV lighting to reveal hidden security features like fluorescent inks, UV-reactive patterns, and watermarks. High-intensity xenon lamps provide broad-spectrum light to inspect microtext and holograms, ensuring authenticity and compliance with security standards.

Barcode Reading

Laser diodes (LDs) are widely used for scanning barcodes, as their focused, coherent beams can read linear and 2D codes efficiently, even from a distance. LEDs are also employed for area illumination, ensuring consistent lighting across the code surface to minimize errors caused by reflections or poor ambient lighting.

Banknote Checking

Specialized lighting, such as UV LEDs, highlights security features like watermarks, holograms, and embedded threads in banknotes. Infrared LEDs are used to detect hidden patterns, while xenon lamps provide bright, uniform illumination to verify microprints and color fidelity. These systems ensure counterfeit detection with high accuracy.

Foreign body detection

Various industries, such as food, pharmaceuticals, and manufacturing, rely on advanced lighting technologies to identify contaminants or unwanted objects. The choice of lighting technology (SWIR, UV and others) depends on the product, the contaminant type, and the operational requirements, such as speed and resolution. Often, a combination of technologies is used for comprehensive inspection.

Fill level analysis

SWIR (Short-Wave Infrared) light sources are ideal for inspecting the fill level of bottles or tablet blister packs. By using SWIR technology, materials that are typically opaque in visible light become transparent, enabling precise detection of contents. This non-invasive method ensures accurate quality control in production lines, helping to identify underfilled or empty sections quickly and efficiently. Its reliability and speed make SWIR light sources a valuable asset in modern packaging and pharmaceutical industries.

Each of these processes is tailored to specific inspection needs, leveraging the strengths of advanced lighting technologies to achieve exceptional precision, reliability, and speed in industrial applications.

contact us